Making commercial vehicle distribution more efficient: leaner and greener…

there is a Better Way Forward

A fixed deck-double decker, in the form of the BWF Wedge trailer, allows you to run a reduced fleet size, resulting in savings of over £150,000 pa and over 100 tonnes of carbon pa for each and every vehicle you take off the road.

The core of the design is a commercial vehicle with a full length, fixed second deck that provides more volume and weight capacity than alternative designs.

Increasing the payload capacity of a vehicle results in:

- Fewer journeys with a smaller fleet

- Lower capital costs and operating costs

- Significantly reduced emissions

- Minimised impact from the driver shortage

Alongside this, with the positive, and needed shift towards greener initiatives within the distribution sector, the benefits from operating a Wedge trailer fleet provide a concrete and immediate step in the right direction for your business and one that will complement whatever might accrue from other initiatives, such as new fuel types or autonomous vehicles, where a number of challenges remain.

The Better Way Forward trailer design is one of innovation. Since its conception, the designs have received Queen’s awards, been granted multiple patents and have delivered significant benefits already to first adopters.

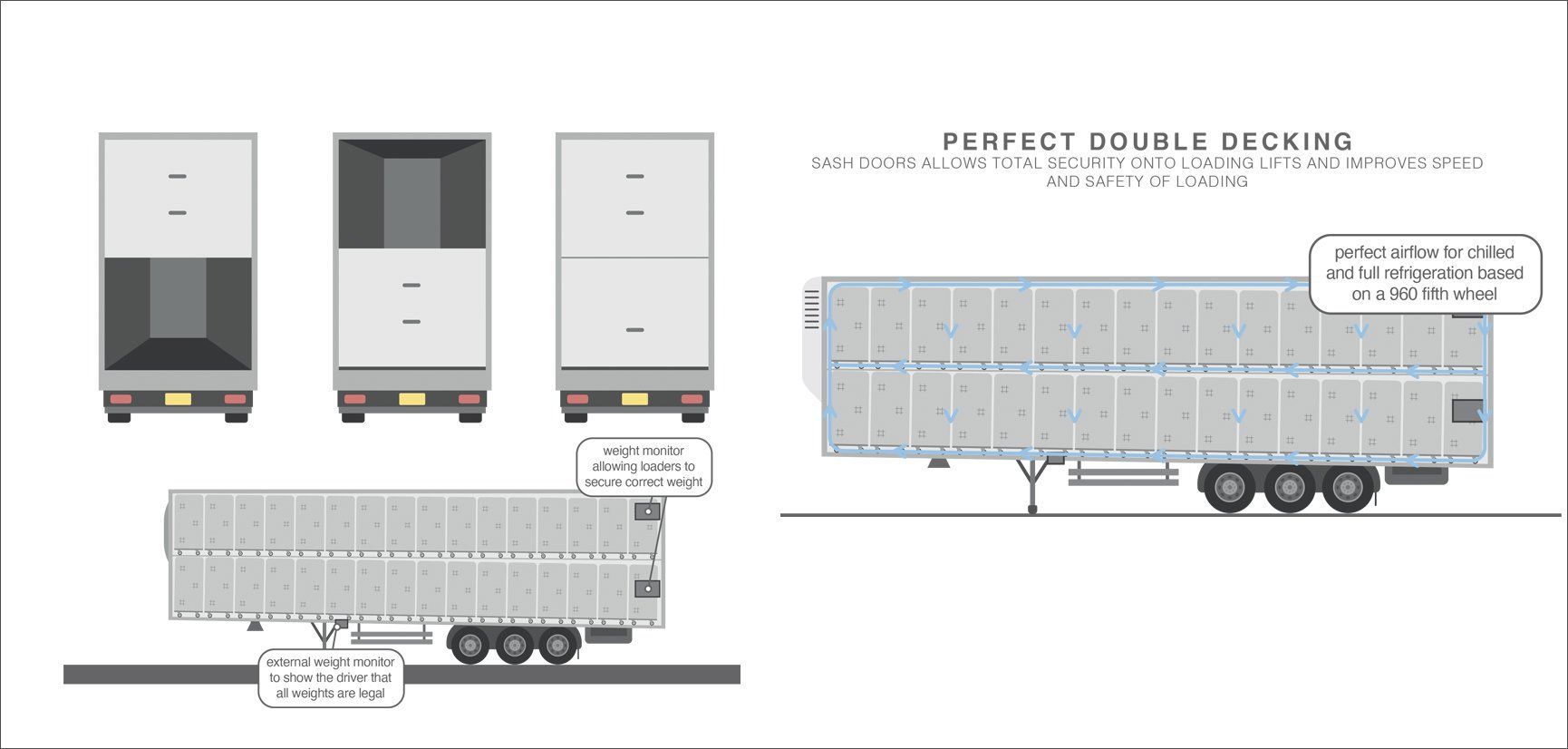

The Better Way Forward Innovation

- A trailer design with a distinctive “gradient kink” that maximises payload capacity (weight and volume) and overall traction

- The sash-style rear doors enhance safety, security, and docking whilst not impinging upon the payload capacity

- A load weight system that monitors the payload weight on each deck and over each axle

- Airflow vents increase air circulation to reduce the size, weight, and operating cost of refrigeration units

- Urban wheel box trailers: a configuration that allows the tail-lift ram box to be located out of the way, at the front of the trailer

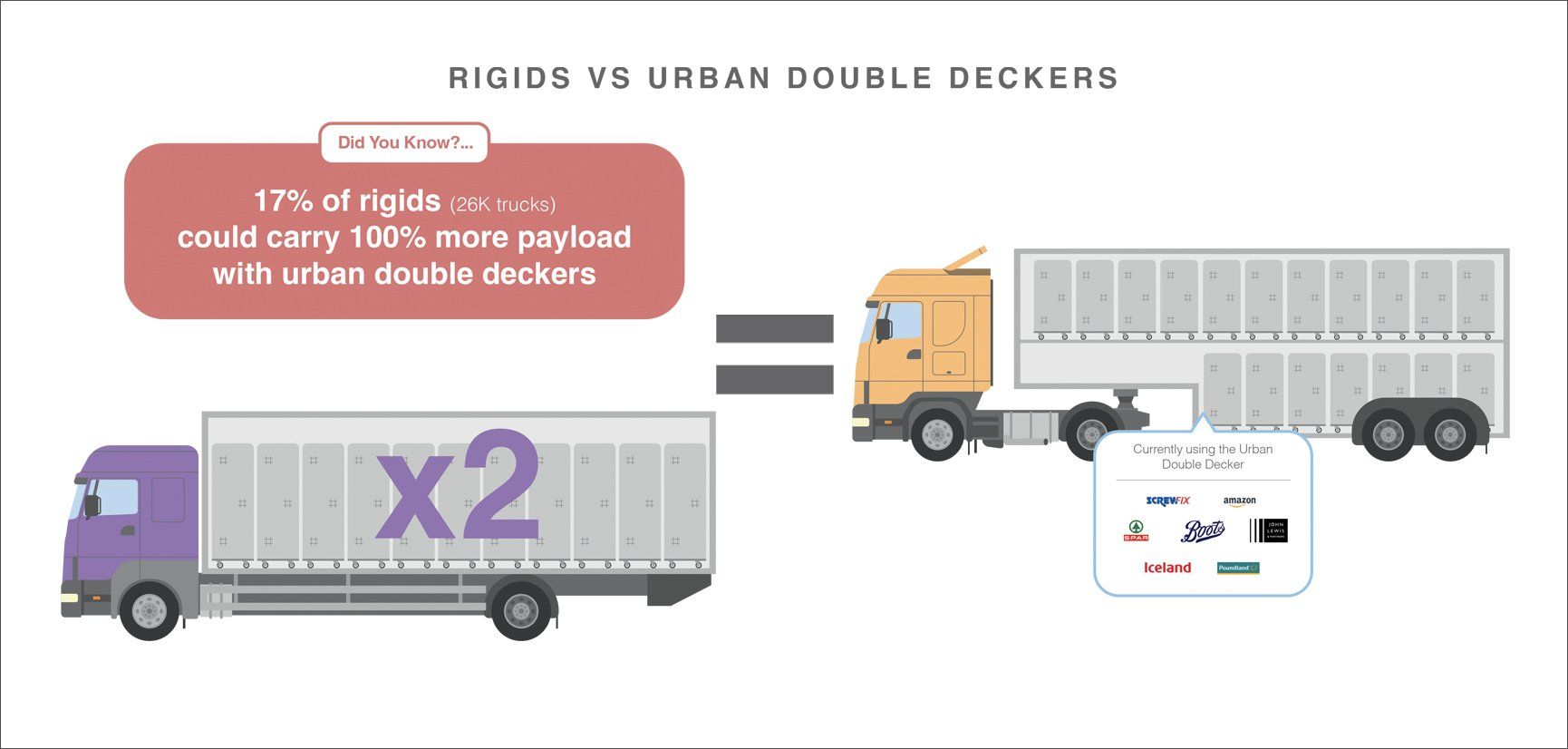

Did You Know?

In the UK, single-decked vehicles continue to dominate commercial vehicle distribution. However, a number of sectors have seen the nature of the payload migrate:

- From larger, heavier, and or loosely loaded goods to smaller, lighter, and often caged goods

- The very sizeable grocery sector, dominated by the major multiples, is the obvious example in this respect

- As a consequence, in such sectors, a fully loaded single-decked vehicle now runs significantly below the gross vehicle weight limit (“GVW”) with the payload capacity constrained by the space offered by the single deck

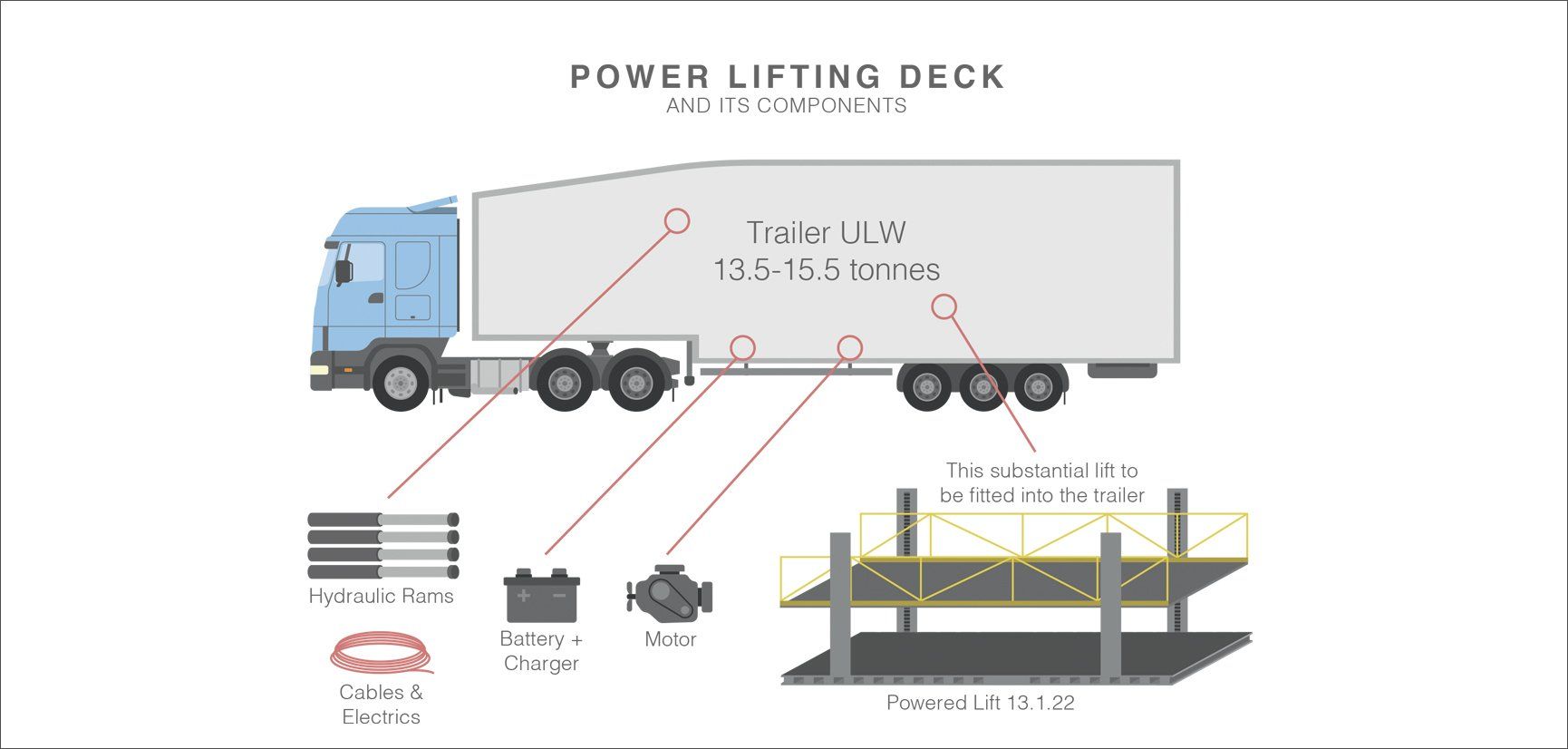

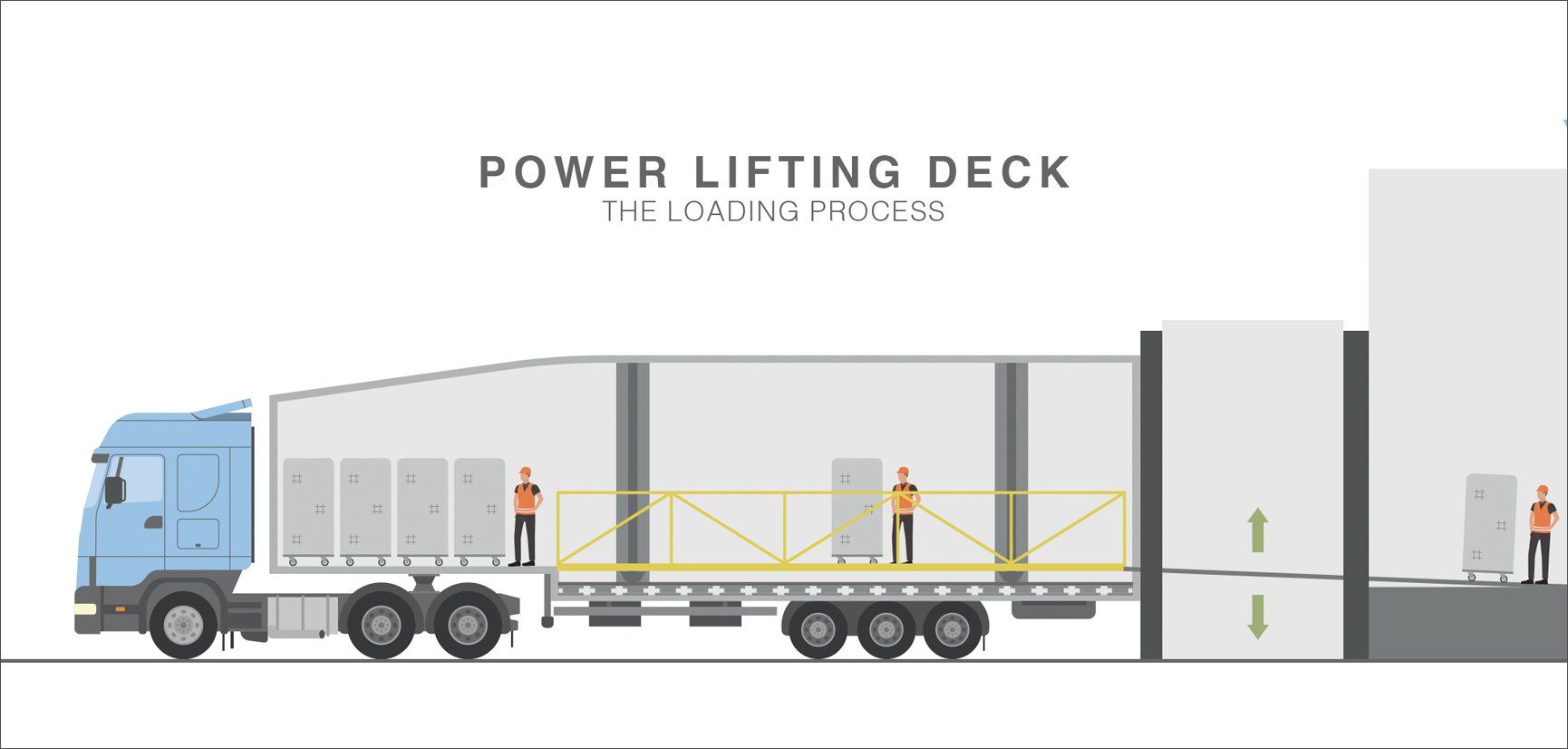

The powered lift double-decker incorporates a moving second deck so as to marry to the “single decker” height of many loading/unloading docks. The fixed deck double-decker incorporates a full length, fixed second deck and is allied to the increasingly common, new wave of “flexible” dock lifts that have emerged to load/unload vehicles of all shapes/sizes. To discover just how these two double-decker designs differ, and how a fixed deck design such as the Better Way Forward Wedge trailer can improve and maximise your payload capacity, let’s delve into the finer details.

The Numbers

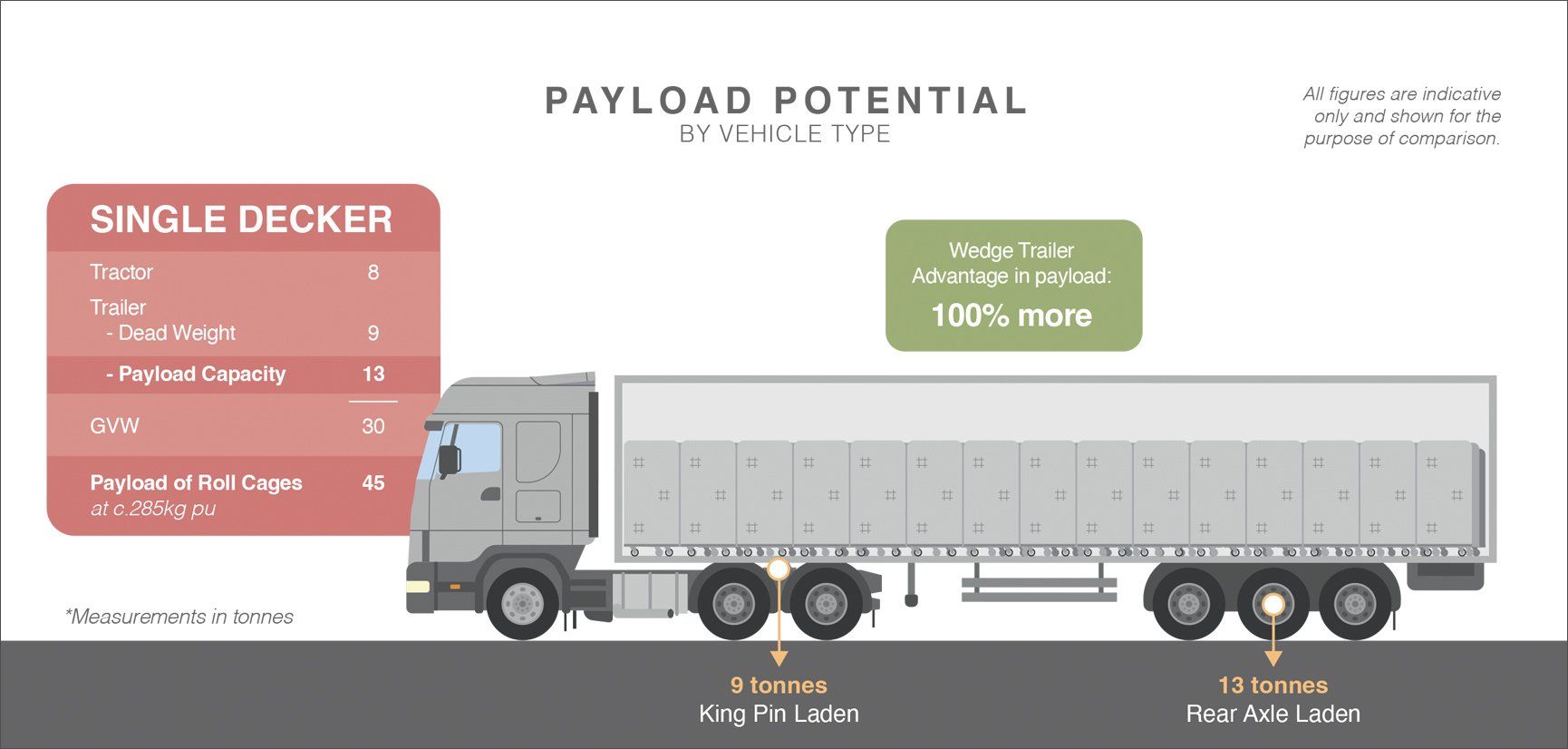

A single-decked vehicle carries around 45 roll cages with an indicative payload of 13 tonnes:

- Here the constraint is created by the single deck

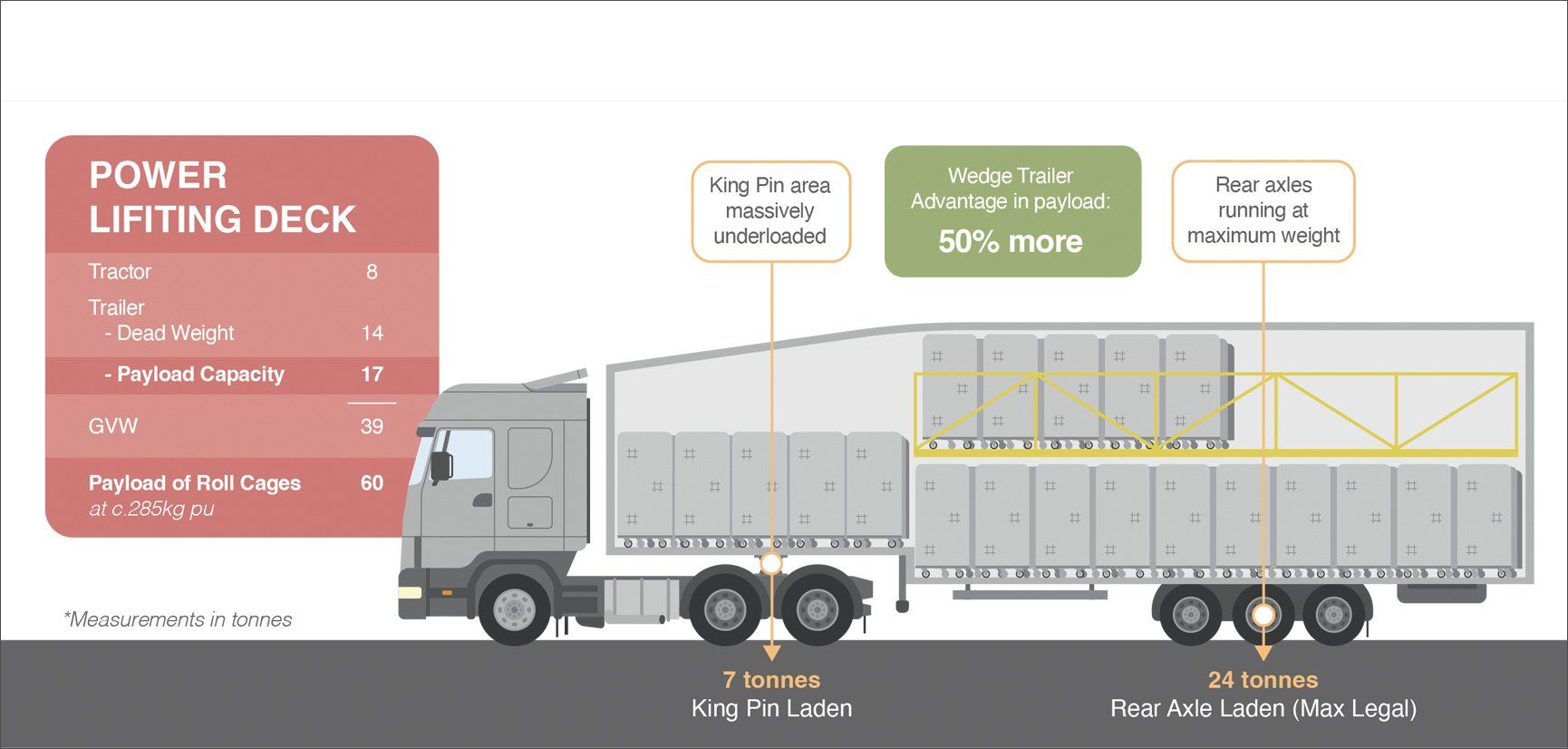

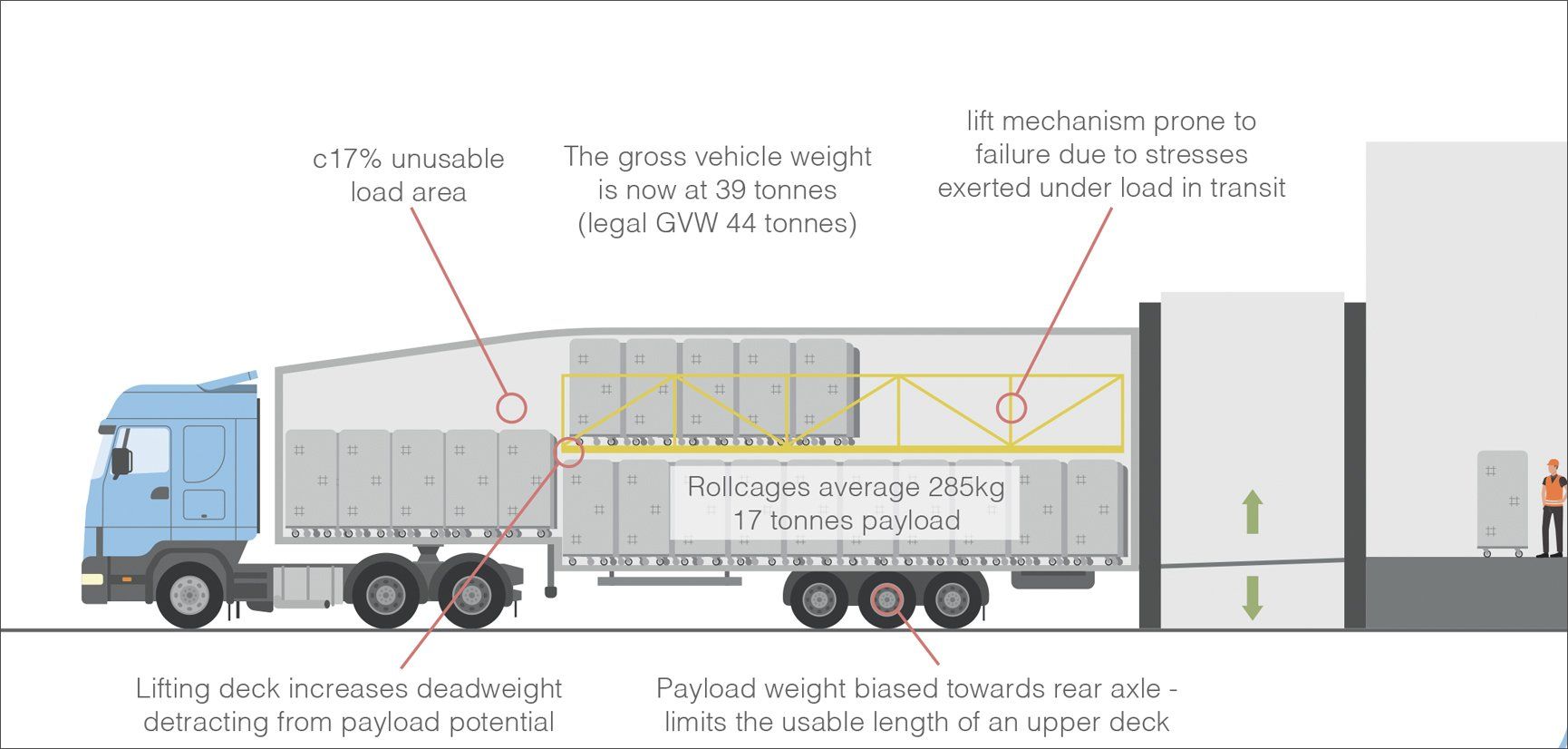

A powered lift double-decked vehicle can carry up to 60 roll cages with an indicative payload of 17 tonnes:

- This design offers more space than a single-decker.

- However, the payload capacity is limited by the additional and considerable deadweight of the powered deck lifting mechanisms…

- …and an inherent load bias upon the rear axles (which can hit maximum load before the GVW limit is reached)

- The unbalanced load also reduces traction - impairing fuel efficiency and safety

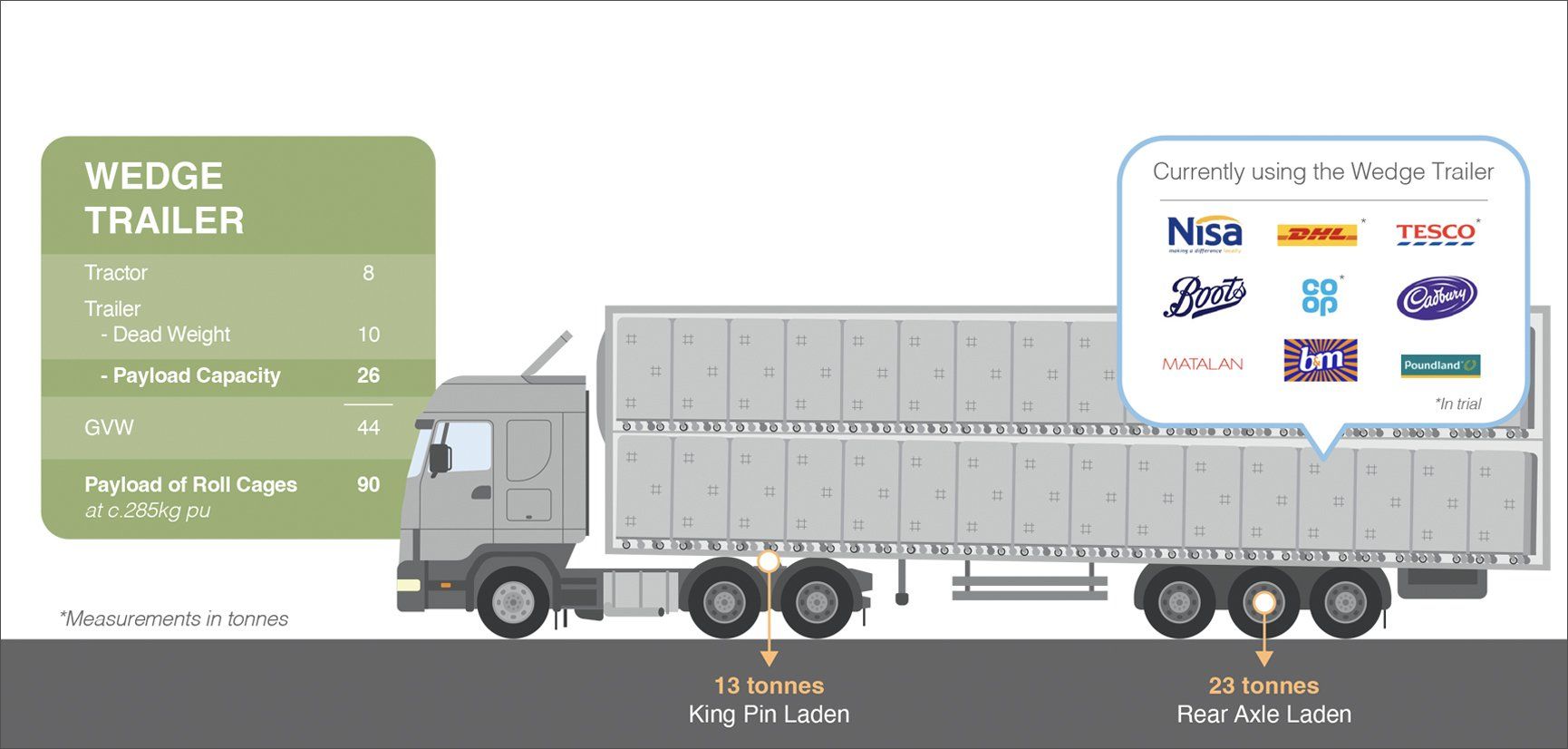

Without these constraints, a double-decked vehicle with a robust, fixed, and full-length upper deck:

- Minimises deadweight

- Maximises usable deck heights (particularly critical in chilled/frozen operations to minimise the reduction in capacity caused by insulation)

- Provides a more uniform load distribution throughout the trailer, avoiding any rear axle bottleneck

The above ensures the fixed deck design maximises capacity in both volume and weight terms, allowing two single-decker loads to be carried in one vehicle carrying 90 roll cages with an indicative payload of 26 tonnes.

What Does This Mean?

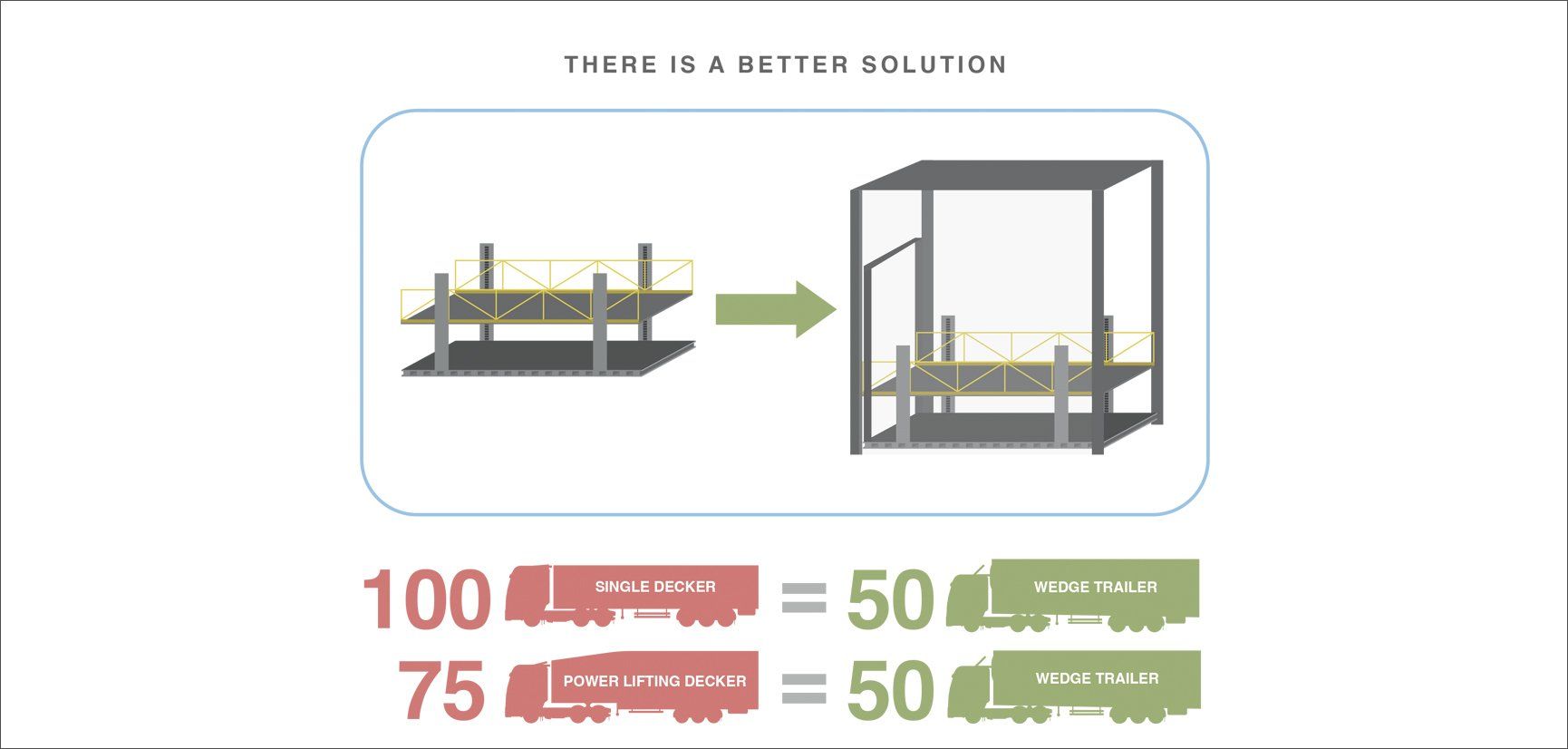

A fixed decker provides much greater payload capacity in both weight and volume terms. In comparison to both the (still dominant) single-decker and the increasingly common powered lift double-decker:

- A 100% gain versus a single-decker and a 50% gain versus a powered double-decker

- 100 single-deckers might be replaced by 75 powered lift double-deckers but just 50 fixed double-deckers would be required

Therefore, reducing a fleet of, say, 100 single-deckers to 50 fixed double-deckers can result in indicative savings of, 50 x £150,000 (and rising) and 50 x 100 tonnes of carbon - per annum.

How To Make The Transition

To date, the favoured transition from single decking has tended to be toward powered lift double-deckers on the basis of the relative simplicity, requiring little if any change in terms of traditional dock infrastructure.

However, the powered lift double-decker can be unreliable in operation, and moreover, as demonstrated above, the payload potential is vastly inferior in comparison to a fixed deck double-decker.

The increasing availability and adoption of more flexible dock lifts has significantly reduced any challenge in transitioning to fixed double-decked vehicles. Even if adopting this might be the more radical strategy, the returns are similarly radical. Moreover, the products are low-tech, proven and available now.

Summary

Faced with a variety of problems:

- Driver shortage

- Escalating costs

- Need to be greener

- Electric vehicle (charging) downtime

- Other initiatives, such as alternative fuels and autonomous vehicles, are not fully proven with respect to efficiency, practicality and or timescale

A readily available, complementary, and significant solution exists:

- Innovative, fixed double-deck vehicles

- That increase vehicle payloads

- Resulting in fewer journeys

- Requiring smaller fleets

- Reducing costs and emissions

- The marriage of lean AND green

…and double-decking is at its leanest and greenest in the form of the Better Way Forward fixed, double-decked “Wedge”.